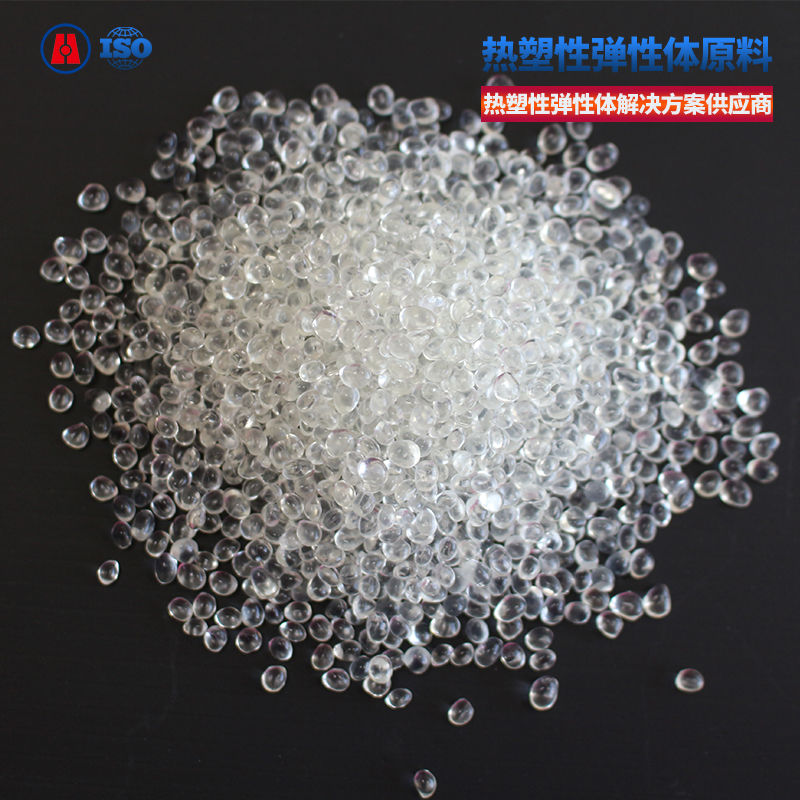

TPU polyurethane elastomer is a multi-industrial thermoplastic material. It has the advantages of high stability and strong pressure resistance. However, synthetic TPU particles require various treatments to form TPU products. So what should be paid attention to in TPU injection molding?

1. TPU material coloring

Except for some special needs, TPU is usually provided in natural colors. Users can easily color the TPU. A straightforward, simple and reliable method is to add toner or masterbatch for coloring. The recommended dosage is as follows: Toner: 0.2-0.5%, Masterbatch: 1-4%

2. TPU material drying

Because TPU is easy to absorb water and hydrolyze, incomplete drying of TPU raw materials can easily lead to processing difficulties. There will be bubbles or silver streaks on the surface of the injected product, and unevenness, dullness, blistering and blistering of the extruded product. In order to ensure zero defects in production and product quality, it is recommended that TPU raw materials must be fully dried to a moisture content of less than 0.05% before processing. If using toner or masterbatch for coloring, it must be mixed with TPU natural colorant and dried together. Typically, circulating air dryers or desiccant dryers are used to dry TPU. According to the hardness, the recommended drying temperature is 80-110, and the drying time is about 3 hours.

What should I pay attention to in TPU injection molding ?

3. TPU material injection molding

Generally speaking, single screw three-stage injection molding machine is suitable for TPU injection molding. Compared with other plastics, TPU has a high viscosity when melted, so it is easy to generate high shear force in the barrel, destroying the physical properties of TPU itself. Generally speaking, an injection molding machine with a screw length-diameter ratio of about 16-20 and a compression ratio of 2.0-25 is more suitable.

4. Handling recycled TPU materials

It can be a nozzle material or a washing machine material where good product is crushed and mixed with new material but must be dried again before use. For some mechanical and physical requirements, the use of recycled materials in the injection molding process is not allowed. It accounts for more than 30% of all raw materials. Extruded recycled material should be processed separately or added to new injection molding material. Also, recycled materials should not be stored for too long. Use dry tops. Non-recyclable waste can be incinerated to obtain heat.

5. TPU material extrusion processing

The regulation and control of injection pressure, holding pressure, injection speed and back pressure are critical to the dimensional stability and release properties of the product. If the holding pressure is too low, the product is easy to sag; if the pressure is too high, it is easy to cause the product to be released. Injection pressure Holding pressure should be adjustable in the range 100-1200bar, injection pressure should be set to only eliminate product pressure drop, holding pressure is usually set to 50% of injection pressure. In order to ensure uniform plasticization, the back pressure should be controlled within 10-25% of the injection pressure.

Holdsuccess

Holdsuccess ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

TEL: +153-0260-7731

TEL: +153-0260-7731

Online consultation: Love Fanfan Consulting

Online consultation: Love Fanfan Consulting

E-MAIL: hdc@winsplas.com

E-MAIL: hdc@winsplas.com

Follow Douyin

Follow Douyin

Follow WeChat

Follow WeChat

Copyright @ 2022 Shenzhen Holdsuccess Industrial Technology Co., Ltd. Guangdong ICP No. 2021175679 Technical Support:mikeidea / Sitemap