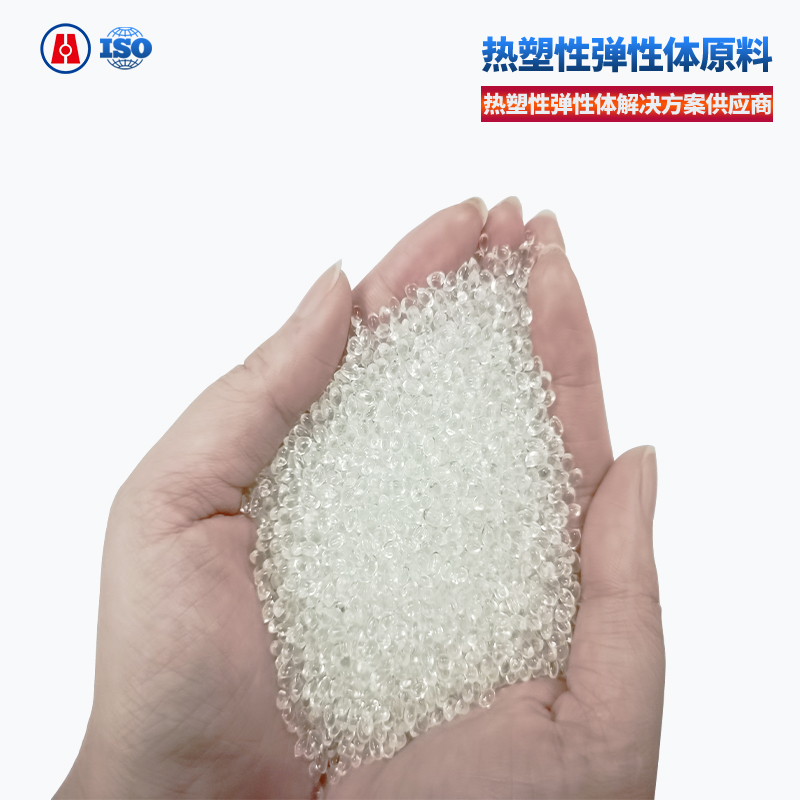

Yesterday, a customer produced a rectangular cover plate, using PC and TPU materials for secondary injection molding, using an ordinary injection molding machine, opening two sets of molds, and two-step injection molding. The first step is to inject the PC cover plate, and the second step is to use TPU material for secondary injection molding. The problem of this step is coming. After the PC product is covered with glue, it is easy to break the PC cover with a little force, and some covers even crack on their own.

Cracking Cause Analysis

PC cracking is relatively common in injection molding, which is caused by the internal stress of molecular orientation in PC is not eliminated. PC will undergo molecular orientation during high temperature melt flow, and molecular rearrangement and de-orientation will occur during cooling. The less flexible benzene ring in the PC molecular structure makes the deorientation process of the PC molecular chain more difficult. If the temperature is lowered too rapidly, or the cooling and holding time is insufficient, the PC molecules cannot be sufficiently relaxed and de-oriented. The sharply increased temperature tends to generate orientation force.

The first step is to inject the PC cover without any problem, indicating that the solution orientation measures are well handled.

In the second step, the secondary injection molding cracked, indicating that the PC cover had internal stress.

The product adopts overmolding, the customer's equipment has no mold temperature control, and the mold temperature is relatively low. The PC cover is also put into the mold at room temperature. When the PC at 20°C and 30°C meets the TPU coating melt at about 200°C, the temperature of the PC cover suddenly rises, and due to the setting of the encapsulation and the glue, the local heating of the PC cover will be uneven. When PC products at room temperature encounter a sudden high temperature, it is prone to internal orientation stress. When using TPU for encapsulation, if the area of the encapsulated part is large, the TPU coating will shrink during the overmolding process, and the PC cover is thin, and the shrinkage of the TPU coating will play a role in the internal stress. to the role of fueling the flames. When the internal stress reaches a certain level, the PC cover will crack naturally.

Cracking Solution Proposal

To eliminate the cracking of the PC cover, it is necessary to eliminate the generation of internal stress.

Bake the PC cover before placing it in the mold. The recommended baking temperature is 80~100℃, bake for 1~2 hours, and then put it into the mold while it is still hot. At the same time, the mold should be set as high as possible, and the mold temperature should be around 70~100℃.

Baking and high mold temperature are adopted, so that the PC cover has a higher initial temperature, and the area of the encapsulated part is large. When it comes into contact with the TPU material melt, there will be no strong temperature change. At this time, even if there is internal stress, It is also very small, so as not to crack the PC parts.

Holdsuccess

Holdsuccess ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

TEL: +153-0260-7731

TEL: +153-0260-7731

Online consultation: Love Fanfan Consulting

Online consultation: Love Fanfan Consulting

E-MAIL: hdc@winsplas.com

E-MAIL: hdc@winsplas.com

Follow Douyin

Follow Douyin

Follow WeChat

Follow WeChat

Copyright @ 2022 Shenzhen Holdsuccess Industrial Technology Co., Ltd. Guangdong ICP No. 2021175679 Technical Support:mikeidea / Sitemap