The processing of TPU materials is mainly divided into melting method and solution method:

Melting method: injection molding, extrusion (casting, blow molding), mixing, calendering, etc. Mainly produces some appearance parts, functional parts and other products. At present, more processes are injection molding and extrusion. These two processes are described in detail later.

Solution method: TPU with low molecular weight is generally soluble in ketone solutions, and TPU with high molecular weight can only be dissolved in strong polar solvents such as DMF. Mainly produces ink, glue, finishing agent and so on.

Matters needing attention in the melting process of TPU materials

: 1. Drying

1. Because TPU is easy to absorb moisture and easy to hydrolyze, insufficiently dried TPU raw materials can easily lead to difficult processing, poor surface of injection products and reduced physical properties of finished products. Therefore, TPU raw materials must be fully dried to a water content of 200PPM (0.02%) before molding. the following.

2. If using toner or masterbatch for dyeing, it must be fully mixed with TPU natural color particles and then dried together.

3. Due to the chemical structure of TPU, TPU particles are exposed to the air and absorb moisture very quickly, especially polyether is more hygroscopic than polyester. Take 95A polyester and polyether as an example, at 25℃, 50%RH:

4. No matter traditional circulating gas dryer or dehumidification dryer, it can be used to dry TPU. Recommended drying conditions are as follows:

| Shore | 60A~80A: 90~100 | 3~5hrs |

| Shore | 85A~98A: 100~105 | 3~5hrs |

| Shore | 60D~71D: 105~110 | 3~5hrs |

Tips: Experienced injection molding technicians will observe the air-shot melt before production: the melt is transparent, moderately soft and hard, no obvious steam, and no foaming in the presence of air, which usually means that the melt is normal. If the plasticized material has foaming or bubbles, the moisture content may be too high.

2. Equipment

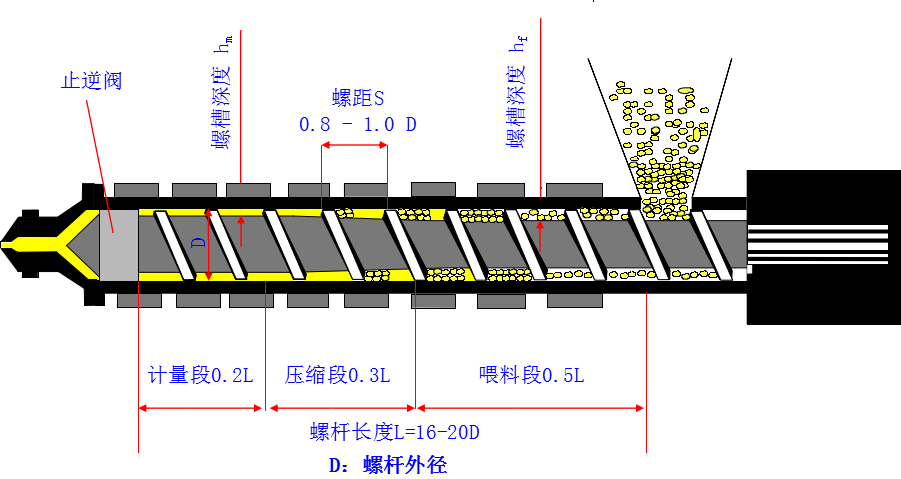

Injection molding equipment: As shown in the figure below, the general single-screw three-stage injection molding machine is suitable for TPU injection molding. Since the TPU material has high viscosity when it is melted, it is easy to generate high shear force in the material tube and destroy the physical properties of the TPU itself. Therefore, the length-diameter ratio of the screw is generally about 16~20, and the compression ratio is about 2.0~2.5. The most suitable for TPU Injection molding of materials . The linear speed of screw speed should be lower than 0.2M/S.

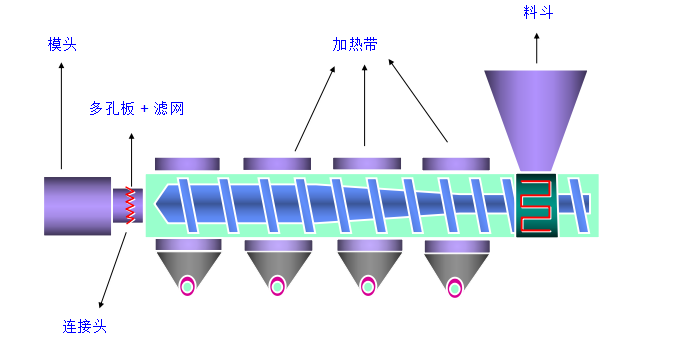

Extrusion equipment: Generally, a single-screw three-stage extruder is suitable for the extrusion of TPU materials , and the L/D range is 20~30, and the compression ratio is 2.5~3.5. The pitch of the screw is the same length as the diameter, the shallow thread depth is better, and the gap between the screw and the barrel is about 0.1~0.2mm. The rotational speed of the screw is set between 30 and 50 rpm. The hole of the perforated plate is about 1.5~5.0mm, and two 400 mesh/cm² filters are used, and two 900 mesh/cm² filters are sandwiched in the middle for best results. However, if it is used for more stringent processing such as film blowing, a finer filter screen is still required.

3. Processing temperature: When the TPU material is injected and extruded, the melt temperature is too high, the material is degraded, and it is easy to produce bubbles, burrs, etc. The temperature is too low, the material flow is poor, and it is difficult to fill the mold. Appropriate processing temperatures are therefore required to ensure material and process stability. The following are recommended processing temperatures:

Recommended setting temperature for injection molding process:

During injection molding, the mold temperature is generally maintained at 25 ° C ~ 45 ° C, and when processing transparent specifications, the mold temperature must be maintained at about 10 ° C.

Suggested setting temperature for extrusion process:

Holdsuccess

Holdsuccess ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 3206A, Tianli Central Business Plaza, Haide 3rd Road, Nanshan District, Shenzhen City, Guangdong Province(Headquarters)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

ADD: Room 606, Building A, Dexing Science and Technology Park, Wusha Xing'er Road, Chang'an Town, Dongguan City, Guangdong Province (Dongguan Branch)

TEL: +153-0260-7731

TEL: +153-0260-7731

Online consultation: Love Fanfan Consulting

Online consultation: Love Fanfan Consulting

E-MAIL: hdc@winsplas.com

E-MAIL: hdc@winsplas.com

Follow Douyin

Follow Douyin

Follow WeChat

Follow WeChat

Copyright @ 2022 Shenzhen Holdsuccess Industrial Technology Co., Ltd. Guangdong ICP No. 2021175679 Technical Support:mikeidea / Sitemap